Understanding Metal Oxide Film Resistors: Construction Principles, Working Mechanisms, Key Specifications and Diverse Applications

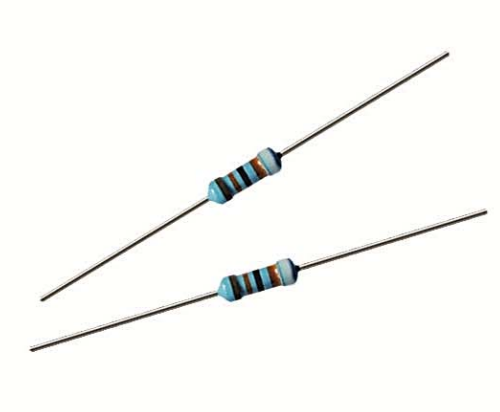

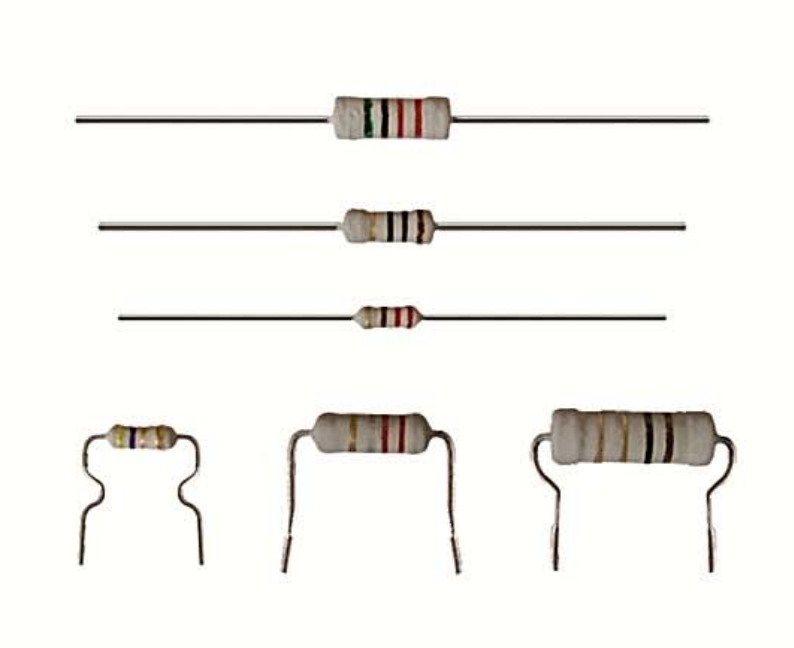

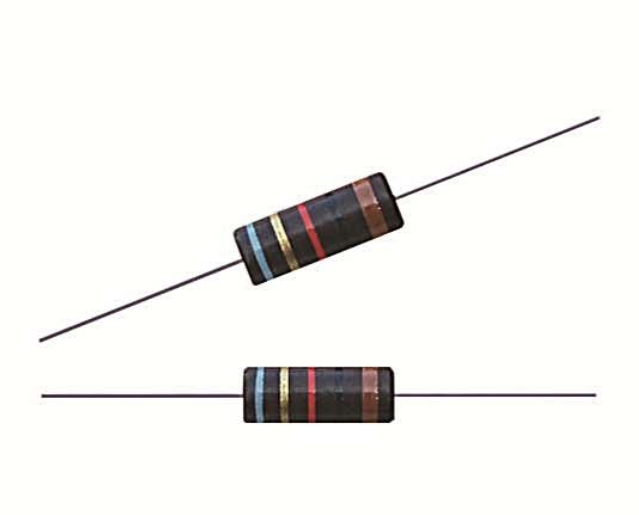

Metal oxide film resistors are essential electronic components. In terms of construction, they typically consist of a ceramic rod or substrate onto which a thin film of metal oxide, often a combination of metals like tin oxide or ruthenium oxide, is deposited. This deposition process can be achieved through techniques such as sputtering or chemical vapor deposition. The metal oxide film serves as the resistive element, while the ceramic base provides mechanical support and good heat dissipation properties.

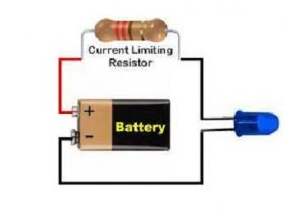

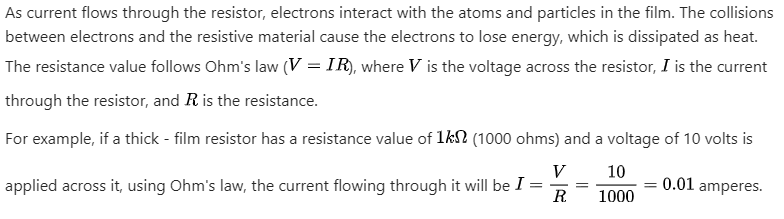

Regarding their working principle, when an electric current passes through the resistor, the metal oxide film restricts the flow of electrons according to its resistivity value. As electrons collide with the atoms in the film, electrical energy is converted into heat, following Ohm's law (V = IR), where V is voltage, I is current, and R is resistance.

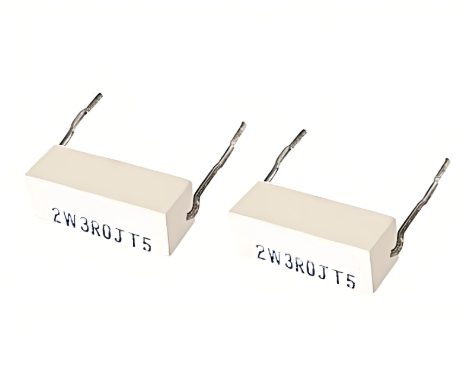

Key specifications include resistance value, which can range from a few ohms to several megaohms, with tight tolerances available for precision applications. The power rating determines the maximum amount of power the resistor can dissipate without overheating, usually ranging from fractions of a watt to several watts. Temperature coefficient of resistance (TCR) indicates how much the resistance changes with temperature; metal oxide film resistors generally have a relatively low TCR, making them suitable for applications where stability over a range of temperatures is crucial.

In terms of applications, they are widely used in electronic circuits. In power supplies, they help regulate voltages and currents by providing precise resistance values. In audio equipment, they contribute to signal conditioning and impedance matching, ensuring high-quality sound reproduction. They are also found in telecommunications devices, where their stability and reliability are vital for maintaining accurate signal transmission. Additionally, in automotive electronics, they withstand the harsh operating conditions and play roles in various control circuits, from engine management systems to lighting circuits.

Email us

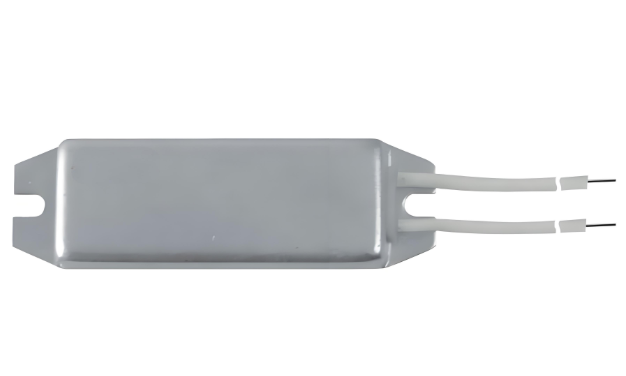

WFL Plastic-Encased Precision Metal Film Strip Chip Shunt

WFL Plastic-Encased Precision Metal Film Strip Chip Shunt BFL Precision Metal Film Strip Chip Shunts

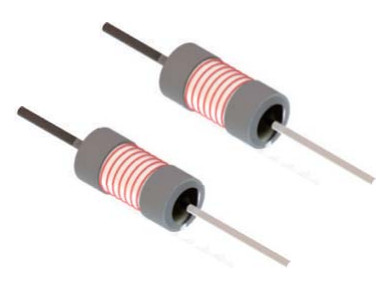

BFL Precision Metal Film Strip Chip Shunts RXF21A/B/C (FRT) wire - wound fusing resistors

RXF21A/B/C (FRT) wire - wound fusing resistors RFX21-T low-power full-short-circuit resistors

RFX21-T low-power full-short-circuit resistors RFX21-D semi-short-circuit surge-resistant wirewound resistors

RFX21-D semi-short-circuit surge-resistant wirewound resistors MZ60 metal-film thermistors

MZ60 metal-film thermistors RF10 painted thin-film fuse resistors

RF10 painted thin-film fuse resistors RF11 porcelain-cased thin-film fuse resistors

RF11 porcelain-cased thin-film fuse resistors RWF molded wirewound fuse resistors

RWF molded wirewound fuse resistors RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors RXF21-TE power-type full-short-circuit temperature fuse resistors

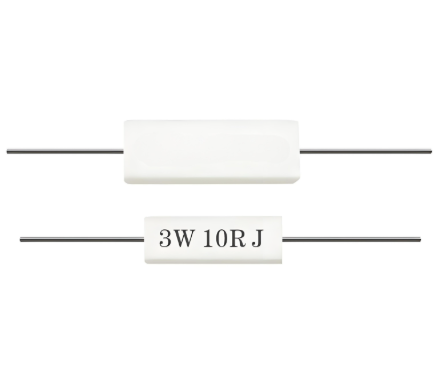

RXF21-TE power-type full-short-circuit temperature fuse resistors RX22 Vitreous enameled wire - wound resistors

RX22 Vitreous enameled wire - wound resistors RX23 ceramic encased wire - wound resistors

RX23 ceramic encased wire - wound resistors RX92 anti - interference wire - wound resistors

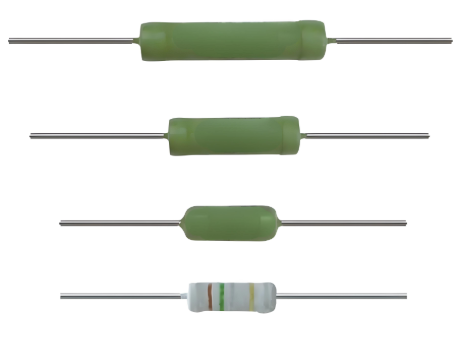

RX92 anti - interference wire - wound resistors RX21 coated wire - wound resistors

RX21 coated wire - wound resistors RXLG high power aluminum encased wire - wound resistors

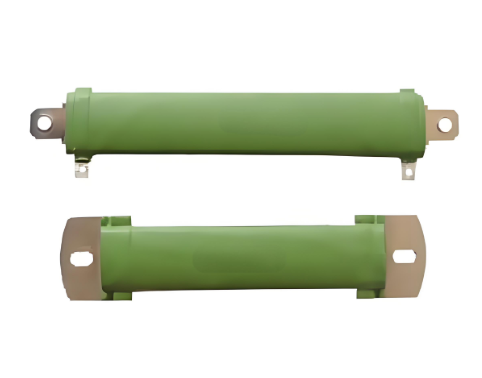

RXLG high power aluminum encased wire - wound resistors RX27 power ceramic encased wire - wound resistors

RX27 power ceramic encased wire - wound resistors RXL power aluminum encased wire - wound resistors

RXL power aluminum encased wire - wound resistors RXHGI high power wane ripple coated wire - wound resistors

RXHGI high power wane ripple coated wire - wound resistors RX20 high power vitreous enameled wire - wound resistors

RX20 high power vitreous enameled wire - wound resistors RX24 aluminum encased power wire - wound resistors

RX24 aluminum encased power wire - wound resistors RXLB power aluminum encased wire - wound resistors

RXLB power aluminum encased wire - wound resistors RXBRXB1 Flat coated wire - wound resistors

RXBRXB1 Flat coated wire - wound resistors REWR huge power circular edge wound resistors

REWR huge power circular edge wound resistors

- High Precision Metal Film Resistors: Ultra-Low Tolerance for Demanding Applications

High precision metal film resistors are highly suitable for a variety of specialized fields, prominently including analog signal acquisition and precision instruments and meters.In the realm of analog...

Resistor Supplies - Jepsun Tech Corporation

JEPSUN INDUSTRIAL is committed to always being one of our customers' favorite suppliers.

+86755-29796190 +8615920026751 [email protected]

Huangjiazhongxin building Donghuan Road Longhua District SHENZHEN City, GUANGDONG Prov. CHINA 518000