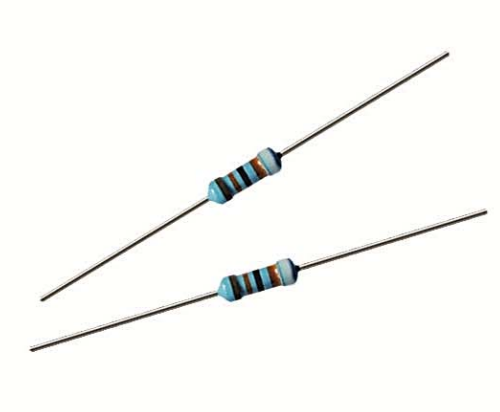

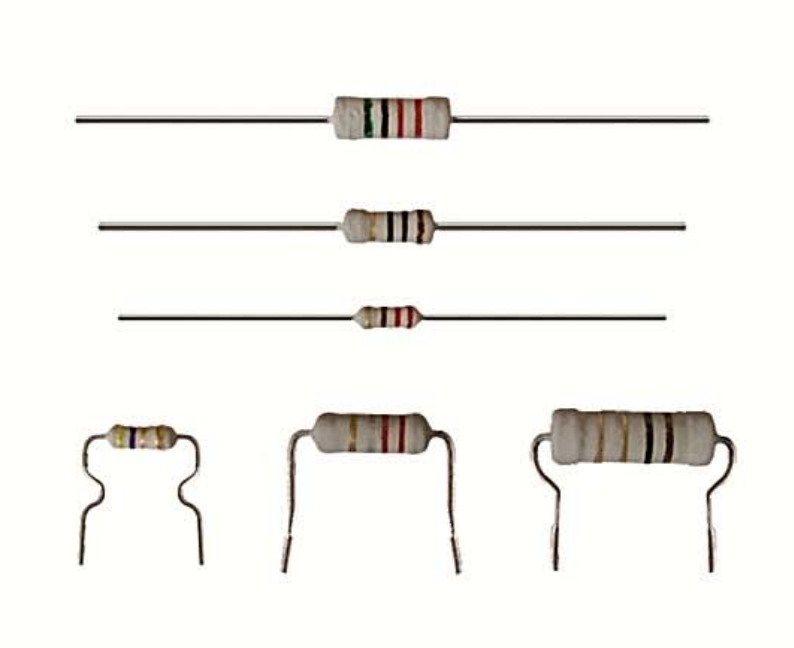

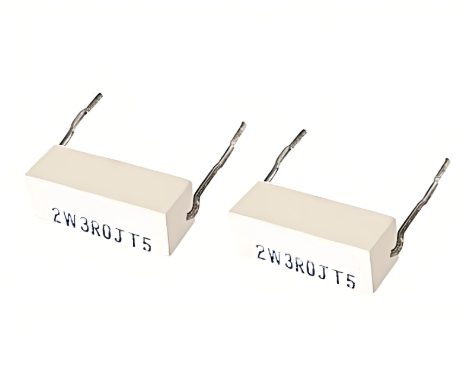

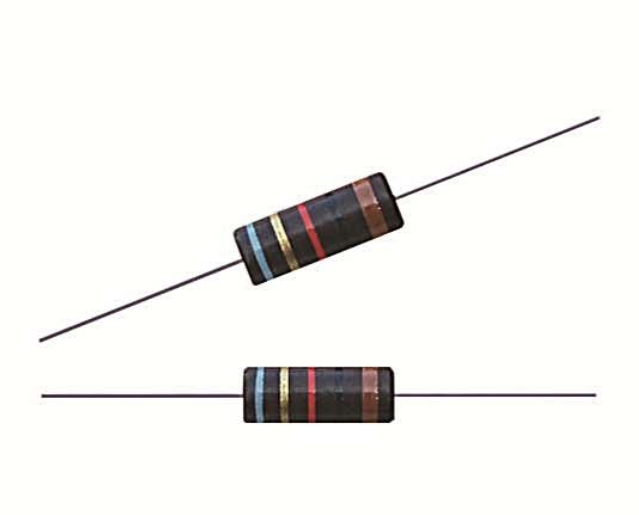

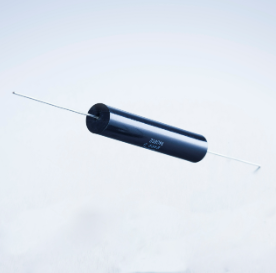

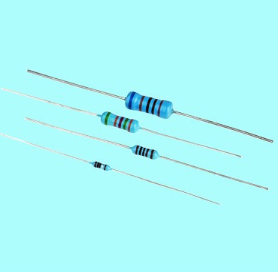

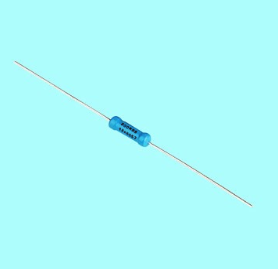

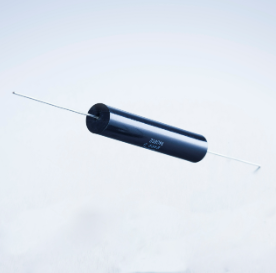

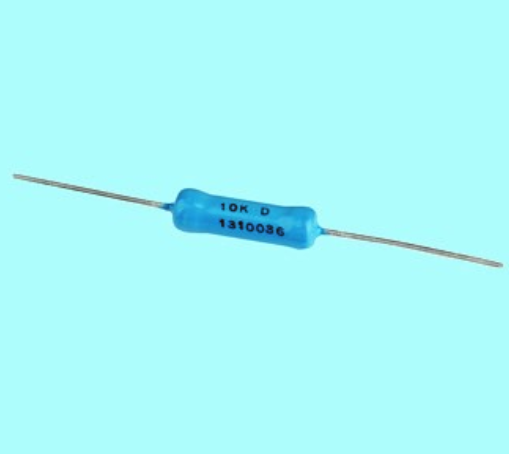

High Precision Metal Film Resistors: Ultimate Accuracy for Critical Circuits

High precision metal film resistors are applicable to fields such as analog signal acquisition and precision instruments and meters.

● Products with military standard certification.

● High stability/high reliability: Molded packaging is adopted.

● High precision: The deviation range of the nominal resistance value is within ±0.01% to ±1.0%.

● Low temperature coefficient: ±2 PPM/°C to ±50 PPM/°C (the test temperature is 25 °C to 85 °C).

● Operating temperature range: -55 °C to +175 °C.

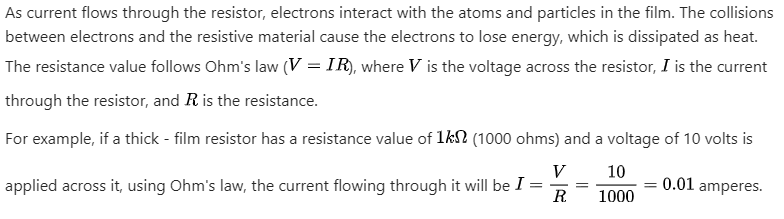

High precision metal film resistors play a crucial role in various electrical circuits, especially those that demand ultimate accuracy. They possess unique characteristics that make them ideal for critical applications.

Features

Manufacturing Process

The manufacturing process of high precision metal film resistors is rather complex and usually involves the following key steps:

Application Areas

Email us

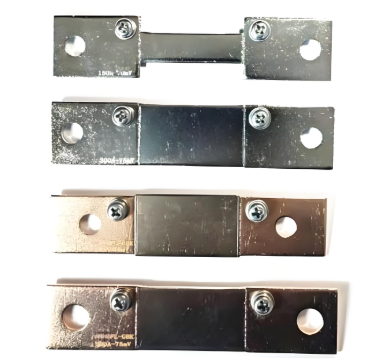

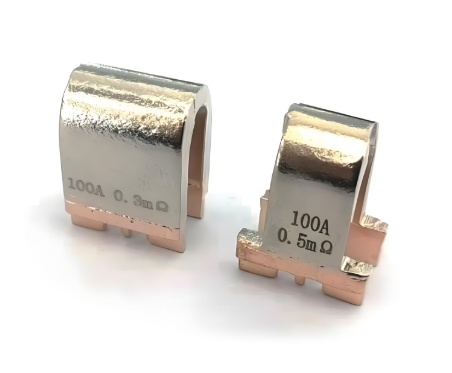

GFL Precision Shunt Resistor

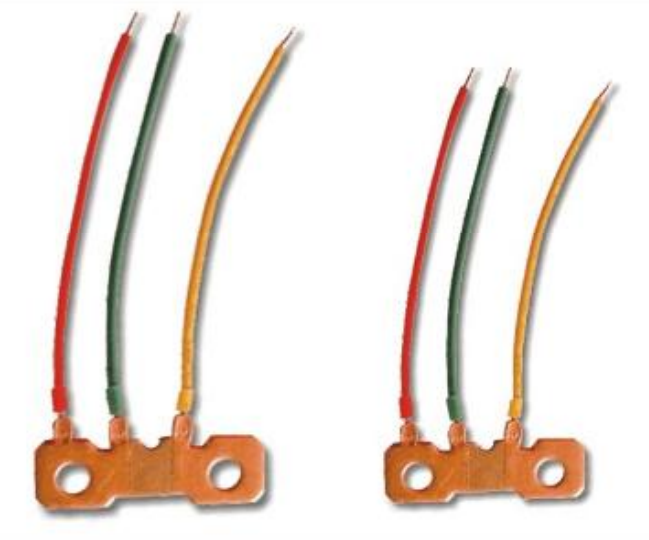

GFL Precision Shunt Resistor WFL Plastic-Encased Precision Metal Film Strip Chip Shunt

WFL Plastic-Encased Precision Metal Film Strip Chip Shunt PFL Precision Shunts for KWH-METERS

PFL Precision Shunts for KWH-METERS BFL Precision Metal Film Strip Chip Shunts

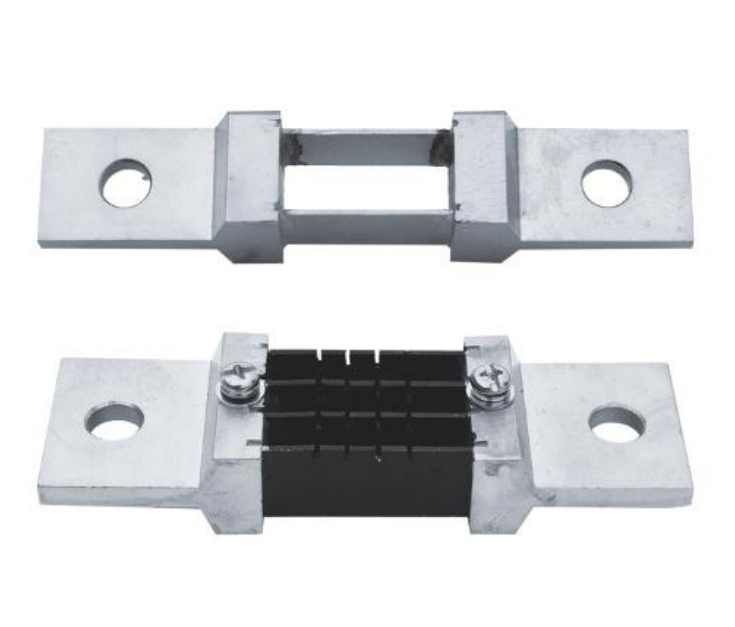

BFL Precision Metal Film Strip Chip Shunts FL-2(T) Precision Shunts

FL-2(T) Precision Shunts FL-1 Precision Shunts

FL-1 Precision Shunts FLQ53 Jumper Precision Shunts

FLQ53 Jumper Precision Shunts RNA/RNB Precision Shunts

RNA/RNB Precision Shunts CFL (M) Precision Shunts

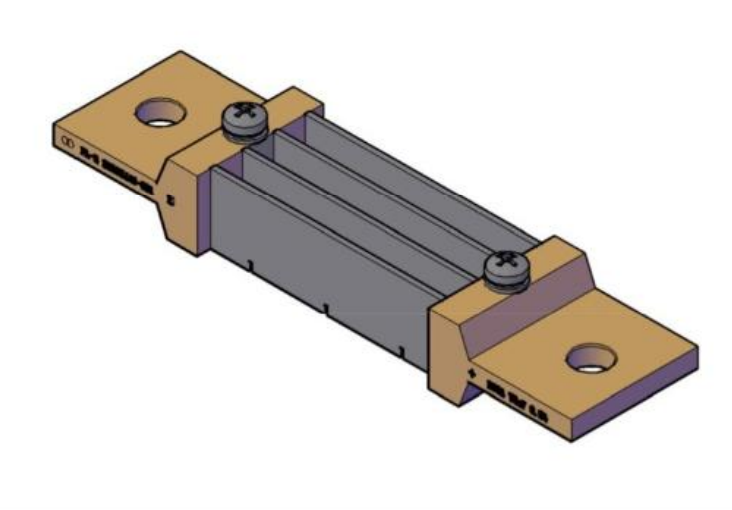

CFL (M) Precision Shunts FL-2-K Precision Shunt

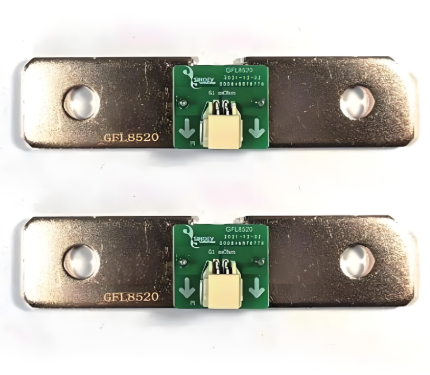

FL-2-K Precision Shunt GFLEV8520 Precision Shunt

GFLEV8520 Precision Shunt GFLEV Precision Shunt

GFLEV Precision Shunt RN1A Precision Shunt

RN1A Precision Shunt UFL Precision Shunt

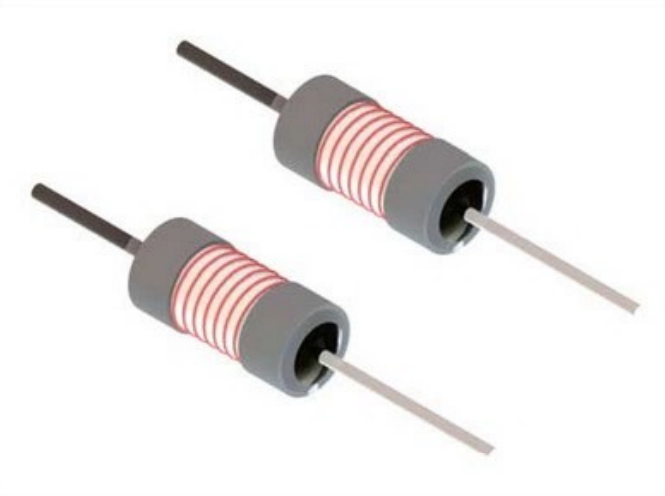

UFL Precision Shunt RXF21A/B/C (FRT) wire - wound fusing resistors

RXF21A/B/C (FRT) wire - wound fusing resistors RFX21-T low-power full-short-circuit resistors

RFX21-T low-power full-short-circuit resistors RFX21-D semi-short-circuit surge-resistant wirewound resistors

RFX21-D semi-short-circuit surge-resistant wirewound resistors MZ60 metal-film thermistors

MZ60 metal-film thermistors RF10 painted thin-film fuse resistors

RF10 painted thin-film fuse resistors RF11 porcelain-cased thin-film fuse resistors

RF11 porcelain-cased thin-film fuse resistors RWF molded wirewound fuse resistors

RWF molded wirewound fuse resistors RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors RXF21-TE power-type full-short-circuit temperature fuse resistors

RXF21-TE power-type full-short-circuit temperature fuse resistors RX22 Vitreous enameled wire - wound resistors

RX22 Vitreous enameled wire - wound resistors

- High Precision Metal Film Resistors: Ultimate Accuracy for Critical Circuits

High precision metal film resistors are applicable to fields such as analog signal acquisition and precision instruments and meters.● Products with military standard certification.● High stability...

- Temperature-Stable High Precision Metal Film Resistors for Critical Designs

Temperature-Stable High Precision Metal Film Resistors are indispensable components when it comes to critical designs in various sophisticated electronic systems.These resistors are meticulously engin...

- High Precision Metal Film Resistors: Optimal Performance for Analog and RF Circuits

In the complex and demanding realm of electronic circuits, high precision metal film resistors have emerged as a linchpin, particularly when it comes to analog and RF (Radio Frequency) circuits, where...

- High Precision Metal Film Resistors: Optimal Performance for Analog and RF Circuits

In the complex and demanding realm of electronic circuits, high precision metal film resistors have emerged as a linchpin, particularly when it comes to analog and RF (Radio Frequency) circuits, where...

- Long-Term Drift Resistance in High Precision Metal Film Resistors

IntroductionHigh precision metal film resistors are renowned for their ability to maintain accurate resistance values over extended periods. The characteristic of long - term drift resistance is a key...

- High Precision Metal Film Resistors: Low TCR for Maximum Stability

In the intricate landscape of modern electronics, high precision metal film resistors have emerged as a vital component, with their low Temperature Coefficient of Resistance (TCR) being a defining cha...

- Advanced Noise Reduction with High Precision Metal Film Resistors

In the realm of modern electronics, noise is an ever-present adversary that can compromise the performance and integrity of circuits. High precision metal film resistors have emerged as a powerful sol...

- Temperature-Stable High Precision Metal Film Resistors for Critical Designs

Temperature-Stable High Precision Metal Film Resistors are indispensable components when it comes to critical designs in various sophisticated electronic systems.These resistors are meticulously engin...

- Achieve ±0.01% Tolerance with High Precision Metal Film Resistors

In the field of electronic components, high precision metal film resistors stand out as the key to applications that demand ultimate accuracy. “Achieve ±0.01% Tolerance” indicates that it is poss...

- High Precision Metal Film Resistors: Ultra-Low Tolerance for Demanding Applications

High precision metal film resistors are highly suitable for a variety of specialized fields, prominently including analog signal acquisition and precision instruments and meters.In the realm of analog...

- High Precision Metal Film Resistors: Ultimate Accuracy for Critical Circuits

High precision metal film resistors are applicable to fields such as analog signal acquisition and precision instruments and meters.● Products with military standard certification.● High stability...

Resistor Supplies - Jepsun Tech Corporation

JEPSUN INDUSTRIAL is committed to always being one of our customers' favorite suppliers.

+86755-29796190 +8615920026751 [email protected]

Huangjiazhongxin building Donghuan Road Longhua District SHENZHEN City, GUANGDONG Prov. CHINA 518000